Hotline:400-668-5636

In battery production workshops, many enterprises are still troubled by such problems: the tapes and buffer pads used for encapsulation need to be die-cut in advance, resulting in considerable material waste; manual bonding is inefficient, and misalignment may occur if not careful; over time, the buffer pads may age and lose adhesion...

In fact, these problems may be solved through a material upgrade — hot melt adhesive encapsulation. Starting from actual production scenarios, let's discuss why it has become a choice for more and more battery enterprises today.

01.

What is common traditional encapsulation?

Most traditional battery encapsulation adopts the combination of "tape with buffer pad". Although this solution is mature, its problems have gradually become prominent in large-scale production:

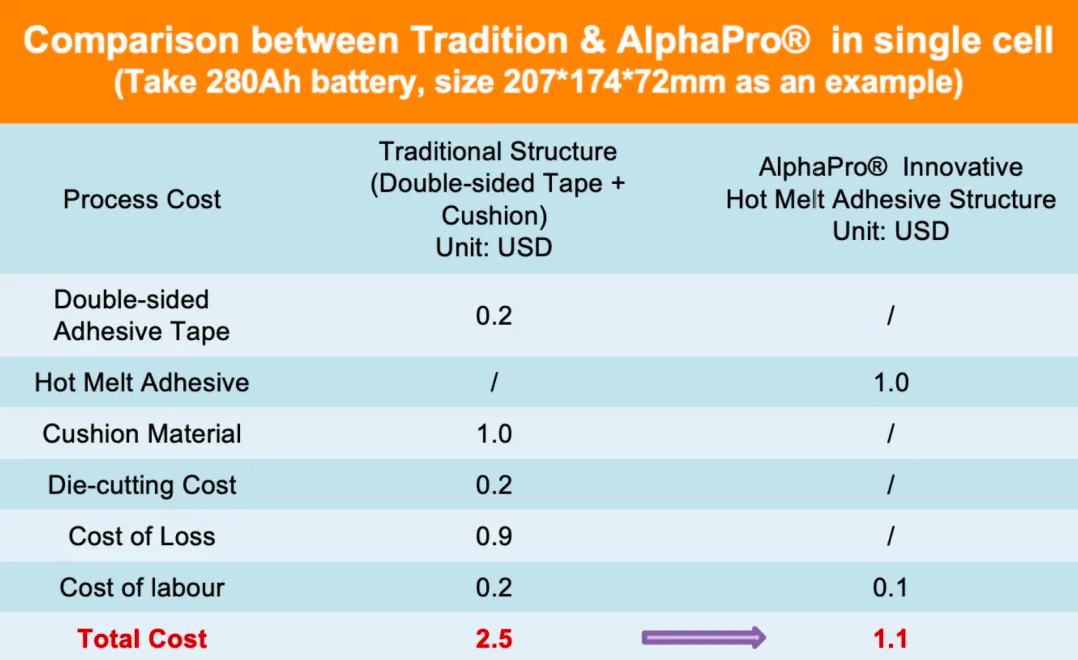

In the material link, for example, buffer pads and tapes need to be die-cut in advance according to the size of battery cells. Once the model of battery cells is adjusted, the previously die-cut parts will be wasted. Calculated, the die-cutting and loss cost per battery cell accounts for 0.8-1.2 CNY. The production link is even more troublesome. Workers have to first stick the tape and then place the buffer pad, and misalignment may occur if they are a little careless. At least 6 workers are required to monitor one production line, leading to high management costs. Moreover, the adhesion of the tape will change with temperature, and the resilience of the buffer pad will deteriorate after long-term compression. Over time, it may cause the battery cells to loosen, affecting the reliability of the battery.

An enterprise engaged in energy storage batteries has encountered similar problems: under traditional encapsulation, the total cost per battery cell is 2.4-3.1 CNY, and the defect rate is always 5‰ due to bonding deviation.

02.

What hot melt adhesive can do?

The core logic of hot melt adhesive encapsulation is to replace "tape + buffer pad" with one kind of material while simplifying the process. From the perspective of practical application, its advantages are mainly reflected in the following aspects:

First, the cost is more controllable. There is no need for advance die-cutting. Hot melt adhesive can be directly sprayed on battery cells through equipment, saving 0.8-1.2 yuan in die-cutting and material loss costs. In addition, automatic spraying can replace manual bonding, reducing the management cost per battery cell from 0.4CNY to 0.1CNY. Calculated, the total cost per battery cell can be controlled at 1.1-1.5CNY, which is more than 50% lower than that of the traditional solution.

Second, the production is more efficient. After the hot melt adhesive is sprayed, it can be bonded firmly after cooling for a few seconds, without waiting for the tape to "exert adhesion slowly". The daily production capacity of a single production line can be increased from 3,000 sets to 4,500 sets. Even if misbonding occurs, the hot melt adhesive can be easily reworked, without tearing off the tape and damaging the surface of battery cells like the traditional method.

Third, the reliability is more stable. After curing, it has elasticity and can "slightly deform" with the expansion and contraction of battery cells during charging and discharging, instead of aging and hardening like buffer pads. Moreover, the adhesive layer is continuous, which can bond the battery cells and the shell more tightly, reducing the risk of loosening.

03.

Compatible with Both Current and Future Batteries

Hot melt adhesive not only solves the problems of traditional batteries but also has advantages in the face of the current popular solid-state batteries:

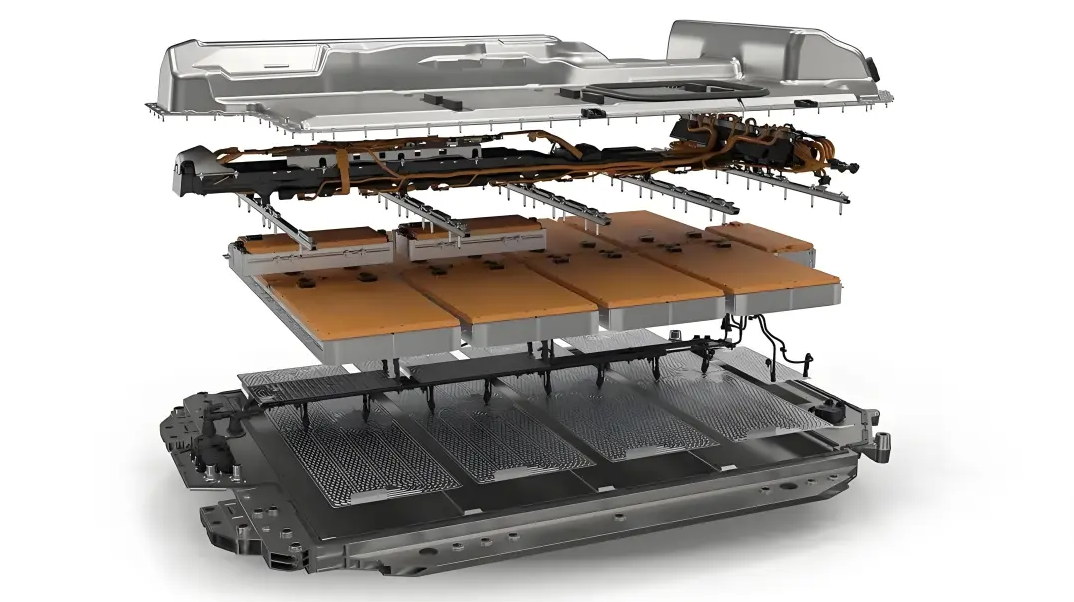

Traditional batteries use liquid electrolytes, and the main concern of encapsulation is liquid leakage. However, the electrolytes of solid-state batteries (such as sulfides) are relatively brittle and afraid of "hard contact" — hot melt adhesive has a soft texture and can act as a "buffer layer" to protect the electrolyte, preventing it from being crushed when battery cells are stacked. In addition, solid-state batteries are often made into multi-layer stacks, and hot melt adhesive can be sprayed into a uniform thin adhesive layer (0.1-0.5mm), which bonds firmly without occupying too much space.

Some enterprises have tried to use it to encapsulate solid-state battery cells. Previously, with traditional tapes, the edge of the electrolyte always cracked. After switching to hot melt adhesive, the defect rate dropped from 3% to 0.5%.

04.

AlphaPro® can offer what?

A power battery enterprise in Jiangsu Province was previously stuck by two problems when using traditional encapsulation: one was high material loss (12% die-cutting waste), and the other was low production line efficiency. After switching to hot melt adhesive, the changes are obvious:

No die-cutting is needed, and the material loss is directly reduced to 3%;

Automatic spraying replaces manual work, increasing the hourly production capacity from 200 sets to 300 sets;

After-sales problems caused by loose encapsulation have been reduced by more than half.

For them, it is not simply a replacement of adhesive, but an improvement in production smoothness, cost reduction, and battery reliability through material upgrading.

In fact, for battery enterprises, the core of choosing encapsulation materials is nothing more than "whether it can solve practical problems" — whether it is to reduce costs, improve efficiency, or pave the way for future solid-state batteries, the hot melt adhesive solution, which is "simple, direct and highly compatible", is worth learning about.

If you also have problems such as die-cutting waste, excessive labor, and unstable encapsulation, or if you want to know whether it can be compatible with your battery cell models (such as soft-pack, prismatic cells), you can leave a message or contact our professional engineers via the QR code below. Talk about your specific scenarios, and we can share corresponding application cases and data!