Hotline:400-668-5636

When discussing "LED packaging", we should not limit the scope to merely protecting the LED chip. —— For most lighting manufacturers, the core requirement lies in "holistic assembly of lighting fixtures": from chip mounting and bracket connections to lamp housing sealing and lens bonding, as well as heat sink installation and screw fastening. All these processes that transform "disjointed components into functional luminaires" – including bonding, sealing, and securing – fall within the scope of LED packaging and assembly.

01.

What is LED packaging?

Simply put, it has two dimensions:

Chip-level packaging: "basic protection" for LED and chip, such as using potting compound to fix the chip and wire to ensure stable light emission;

Light fixture assembly: connect the chip module, shell, lens, heat sink and other components into a complete lamp, such as the shell and glass cover of street lamp sealed, the lens and bracket of shopping mall lamp glued, and the heat sink and body of parking lot lamp fixed.

For most lighting fixture customers, the latter (component bonding assembly) material selection directly affects the structural stability, waterproofing, heat dissipation efficiency and service life of the lamp.

02.

Why do you need a professional LED packaging and assembly solution?

Lighting devices have to go through three tests of "production efficiency, scene adaptation and long-term stability" from production to use, and packaging and assembly materials are the key support:

• Improve production efficiency and reduce labor costs

Traditional lamp fixture assembly uses screws, clips and other mechanical connections, which require manual alignment and tightening. A single production line can only assemble 50-80 sets per hour. After replacing with adhesive, the coating can be automated, and the efficiency can be increased to 200-300 sets/hour, and the manual alignment error is reduced (the defect rate of traditional screw fixation is about 5%, while the adhesive can be reduced to less than 1%).

• Adapt to complex scenarios and meet functional requirements

Different lighting scenes have very different requirements for lamps: For example, the shell of outdoor street lamps needs to be IP67 waterproof, otherwise rainwater infiltration will cause short circuit; magnetic lights in shopping malls need to be light and thin to hide, because traditional screws will damage the appearance, transparent adhesive achieves "seamless fixation"; The connection of components in intelligent lighting needs to be impact-resistant and high temperature resistant above 1 60℃ to prevent vibration and detachment caused by danger.

• Ensure long-term stability and reduce maintenance costs

Once the lamp is installed, the maintenance cost is extremely high (for example, the replacement cost of a street lamp at high altitude exceeds 1,000 yuan). For example, once the sealing glue fails to waterproof, it will lead to the rusting of internal components and shorten the life to 1-2 years; The adhesive of the heat sink is not firm, resulting in poor heat dissipation and LED brightness decreases by more than 10% every year; the lens is detached, resulting in scattered light and reduced lighting effect by 30%.

03.

How many ways forLED packaging and assembly material solutions?

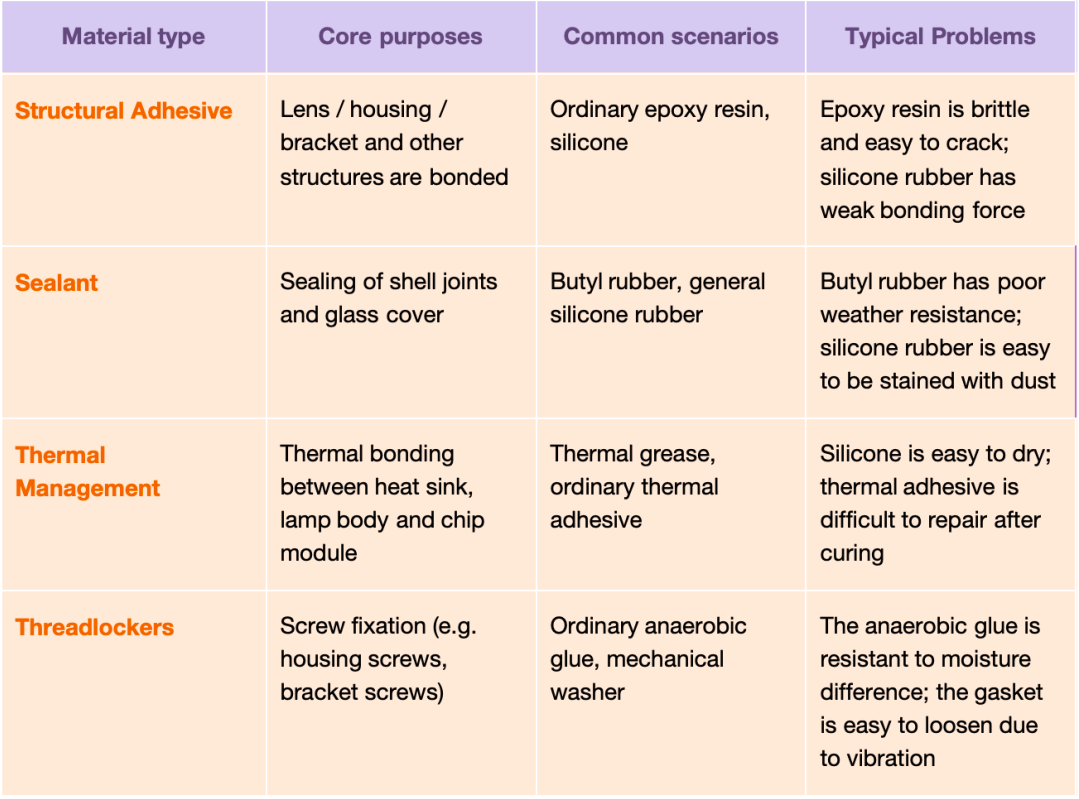

At present, the commonly used materials for lighting device assembly mainly focus on four major requirements: "structural bonding, sealing and waterproofing, heat conduction and fixation, and thread locking", but there are still limitations in complex scenarios:

For instance, outdoor streetlights using standard silicone rubber sealed casings develop cracks from UV-induced aging within a year, allowing water infiltration that causes internal short circuits. Similarly, mall lighting fixtures employing epoxy resin lenses become brittle in winters low temperatures, resulting in a 15% lens detachment rate. These critical challenges highlight the essential breakthroughs required by specialized LED assembly materials.

04.

AlphaPro® How to solve it?

To address the core pain points of lighting device component bonding, AlphaPro combines commercial intelligent lighting (outdoor street lights, shopping mall lighting, industrial lighting, etc.) scenarios, and uses three materials to achieve "stable structure, strict sealing, good heat dissipation, and secure fastening":

Outdoor LED screens are prone to minor issues. —— During rain, water seeps through edges causing blackouts, and prolonged use may lead to yellowing – all stemming from improper encapsulant selection. The AlphaPro® GOB system uses encapsulant 8902 that forms a flexible protective layer after curing, effectively blocking rainwater while maintaining over 95% light transmittance. Even after two years of sun exposure, it resists yellowing. Concert equipment manufacturers have observed that screens previously requiring 10% maintenance after rainy performances now require minimal adjustments. Screens in use for over a year retain colors as fresh as new.

Thin lamp assembly is also a headache. If you want to make it thin, you cant use thick thermal pads, and fixing the heat sink with screws is slow and heavy. AlphaPro® Thermal adhesive tape 0257 is only 0.25mm thick, attached between the heat sink and the lamp body, the thermal conductivity is half better than ordinary tape, the adhesion is strong, no need to screw. A customer who makes industrial lighting in Zhongshan used it, the production line speed was halved, and the lamp life was extended from 3 years to 5 years.

Parking lot and swimming pool light screws pose particular challenges. Not only do vibrations from passing vehicles loosen them, but the humid environment also accelerates rusting. During maintenance, workers often have to forcefully tighten screws, which can easily damage the lamp casings. AlphaPro® Anaerobic Locking Adhesive 7288 effectively fills screw gaps when applied, preventing loosening during vibrations. Its moisture barrier properties make it ideal for marine and pool environments, where screws remain rust-free for up to three years. The adhesive cures quickly – a single application can reattach a screw in just 10 minutes. We tested this solution on a swimming pool lighting project in Dalian. Previously, 20% of fixtures required casing replacement due to screw corrosion, but now this issue has been virtually eliminated. Maintenance becomes significantly easier with the adhesive, requiring minimal effort to tighten screws.

05.

Advantage migration of semiconductor packaging: from "chip level reliability" to "light fixture level durability"

AlphaPro's materials are designed to adapt to complex lighting installation scenarios, with the core innovation being the transfer of semiconductor packagings "high precision and high reliability" technology to LED lamp assembly. —— The assembly environment for semiconductor chips (high temperature, high cleanliness, vibration resistance) is more stringent than that of LED lamps. This technological expertise naturally endows LED materials with a "dimensional reduction advantage":

• Material formula migration: from "semiconductor weather resistance" to "lamp aging resistance"

Semiconductor chips need to work stably for 10 years at-55℃~125℃. AlphaPro uses this "weather-resistant formula logic" to LED materials:

• Process standard migration: from "semiconductor precision" to "luminaire consistency"

Semiconductor packaging requires material thickness tolerance ≤±0.02mm (otherwise it will affect chip heat dissipation), this standard is used in LED material production:

• Reliability test migration: from "long life of semiconductor" to "low maintenance of lamps"

Semiconductor materials need to pass "1,000 cycles of high and low temperature" and "1 million vibration tests", and AlphaPro has implemented this test standard for LED materials:

If you encounter problems such as "inadequate bonding, failure of sealing, poor heat dissipation, loose screws" in the assembly of lamps, please scan the code to contact your exclusive engineer, or apply for AlphaPro product sample test —— Let semiconductor level reliability become the confidence of lamp competitiveness.