Hotline:400-668-5636

In everyday life, from mobile phones and computers to electric cars, many products are glued together with adhesive. While this permanent bonding holds parts in place, it makes maintenance, upgrades, and recycling difficult —— Changing a part may break the entire device, and its hard to separate the materials when recycling.

To address this issue, AlphaPro® has developed the debonding-on-demand technology.

Simply put, it ensures that the adhesive is strong when needed and can be easily separated when no longer required, leaving no residue behind. This technology not only reduces waste but also makes products easier to repair and recycle, aligning with the principles of a circular economy.

01.

What is Debonding on Demand?

The core of debonding-on-demand is to introduce a trigger mechanism into the tape, such as heat, electricity, or UV light, which causes the adhesive to lose its stickiness. Currently, this type of tape is increasingly being used in products like mobile phones, car displays, and electric vehicle batteries. If the wrong part is installed during production, it can be removed and re-adhered; after the product is scrapped, the parts can be fully disassembled and reused or recycled, significantly reducing resource waste.

Debonding-On-Demand technology is not isolated; it is closely linked with other cutting-edge technologies like artificial intelligence and the Internet of Things, mutually enhancing each other. For instance, in smart factories, IoT technology enables devices to monitor their operational status and the bonding condition of components in real time. When a component needs replacement, the system can automatically issue instructions to perform on-demand debonding through specific methods (such as precise heating of components using thermal debonding technology). This allows maintenance personnel to quickly and damage-free disassemble the equipment, significantly boosting production efficiency.

02.

Take EV batteries as an example:

the coordination of de-bonding, disassembly and recycling

In the life cycle of electric vehicle batteries, "good disassembly" can "good collection", and on-demand de-bonding technology plays a key role in this:

✓De-bonding: The adhesive is loosened under specific conditions (such as a certain temperature) according to the design, so that the battery unit, shell and other components can be completely separated without damage. For example, the AlphaPro® 1210 tape is fast to assemble, but can be mechanically removed after the battery is scrapped.

✓Disassembly: the whole battery pack is disassembled step by step, including the battery unit, control system, etc. With the adhesive removal technology, the disassembly is more labor-saving and does not cause damage to parts due to hard disassembly.

Take electric vehicle batteries as an example: the coordination of de-bonding, disassembly and recycling

✓Recycling: lithium, nickel, cobalt and other materials are recovered from the disassembled parts. There is no residue after degumming, and the materials can be reused more purily.

These three steps are linked together, and the removal of adhesive is the basis. —— Only when the adhesive is firmly attached and the disassembly is smooth can the recycling be more efficient, which not only complies with environmental regulations, but also helps the industry achieve emission reduction goals. At the same time, for dangerous lithium batteries, controllable de-adhesion can reduce the safety risks during disassembly.

03.

How many ways to debond?

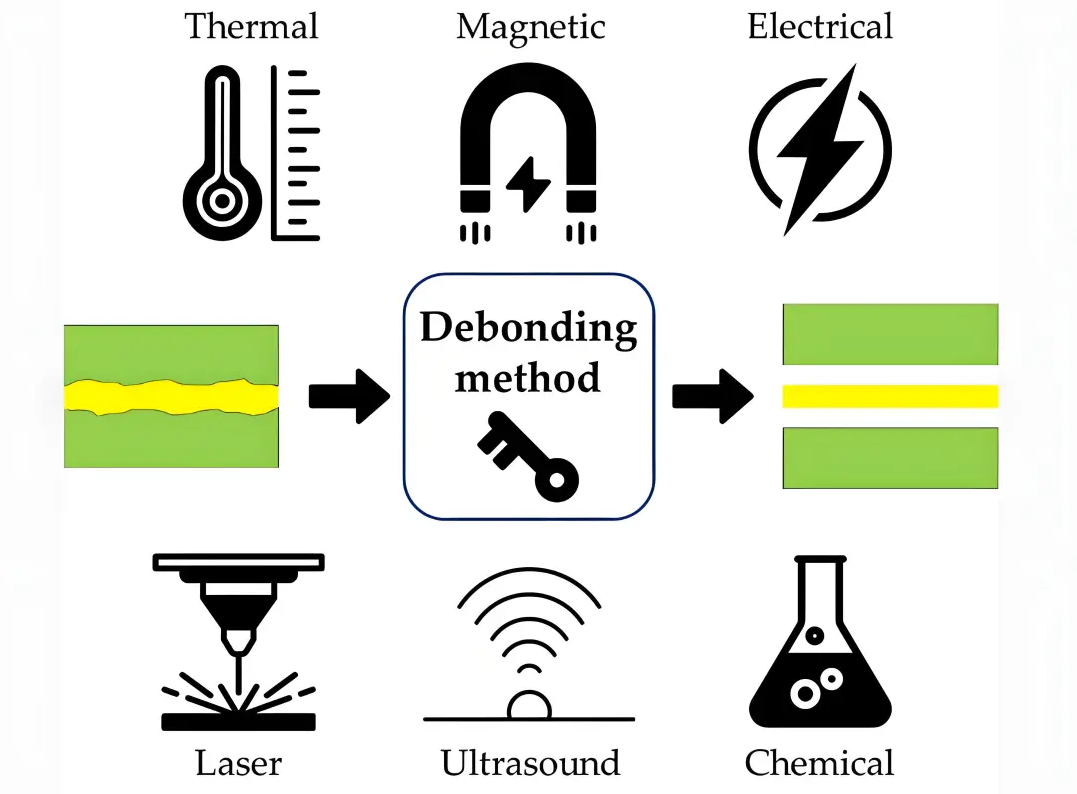

At present, the industry is trying a variety of "trigger methods" to achieve decoupling:

🔖Thermal debonding: a very common way. The adhesive is stable at room temperature, but when heated to a specific temperature, the adhesive will foam and become soft, which is convenient for separation;

🔖Electrical Debonding: The principle involves triggering a chemical reaction with low voltage, which can release the adhesive within seconds. AlphaPro® 1210 electric adhesive tape uses dynamic cross-linking technology to control the peel strength of the tab bonding at 15-25N/25mm, ensuring both robustness and separation as needed. Additionally, it can withstand temperatures up to 120℃, aiding in the maintenance of power battery tabs and anti-explosion films, thereby improving the pass rate of thermal diffusion tests for energy storage systems;

🔖UV debonding: The principle involves using specific wavelengths of UV light to decompose the adhesive, making the separation process gentler. AlphaPro® 6595 UV adhesive is highly versatile and can be applied to PET films or other optical films. Before desorption, the adhesion strength can be adjusted between 1000g and 2500g, and after desorption, it drops below 40g, allowing for customized development as needed;

🔖Other methods: for example, chemical solvent debonding, ultrasonic debonding, magnetic debonding, laser debonding, or directly use AlphaPro® 8281 Easy-tear to reduce the viscosity by stretching the label and then manually remove it.

04.

Changes brought to all walks of life

🔖 Electronic industry: There may bemore than 80 kinds of tapes in a mobile phone to fix the screen, battery and other parts. By using the adhesive film, the parts can be replaced separately when repairing the phone, which can prolong the life of the equipment; if the production is wrong, it can be reworked, reducing waste.

🔖Automotive industry: There are already many applications on the dashboard display, and there is more potential in the future for electric vehicle battery installation, sealing and other aspects. For example, the camera and radar module of advanced driver assistance system (ADAS) can be used to extend the service life and reduce the replacement cost with adhesive technology.

🔖Aerospace: During the manufacturing and maintenance of aircraft, on-demand debonding technology ensures that components remain securely connected during flight. It also allows for safe and efficient disassembly during regular maintenance or upgrades. This not only enhances the efficiency and reduces the costs of aircraft maintenance but also provides greater flexibility for performance optimization and technological upgrades, thereby boosting the international competitiveness of Chinas aerospace industry.

05.

Future cooperation & innovation by AlphaPro Chemical

AlphaPro® plans to integrate the release technology into more products. We believe that each industry has unique needs, and there is no one-size-fits-all solution. Therefore, in addition to our existing tape products, we will also customize release solutions tailored to specific customer requirements, from design, testing to optimization, providing comprehensive support throughout the process.

If you want to know how to apply the release technology to a certain product, or have customized requirements, please leave a message for discussion, or you can also consult —— through the background to find more efficient and environmentally friendly bonding and separation solutions together.