The concept of CPO (Co-Packaged Optical) has been a hot topic in capital markets recently. As of now, the CPO sector has surged over 120% year-to-date, with industry leaders like InnoLight and XinYiSheng delivering particularly impressive performance, both seeing gains exceeding 150%. This surge stems from the explosive growth in AI computing demands. With the rapid development of large models like ChatGPT 5.0, data centers now require skyrocketing data transmission speeds.

CPO technology has gained traction among global tech giants worldwide for its ability to co-package optical engines with switching chips, significantly boosting transmission efficiency. Major international cloud service providers including Microsoft, Google, and Amazon have announced deployments of CPO in their data centers. NVIDIA has further integrated CPO technology into its latest Spectrum-X silicon photonics switching chips to meet ultra-high computing demands.

Domestically, Huawei and ZTE are actively advancing R&D and application of related technologies. In the implementation of CPO technology, critical materials such as UV-curable curing agents and thermal management materials play indispensable roles.

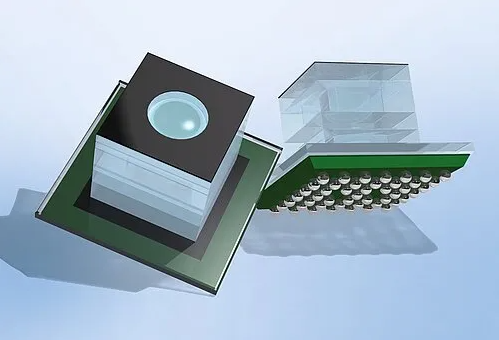

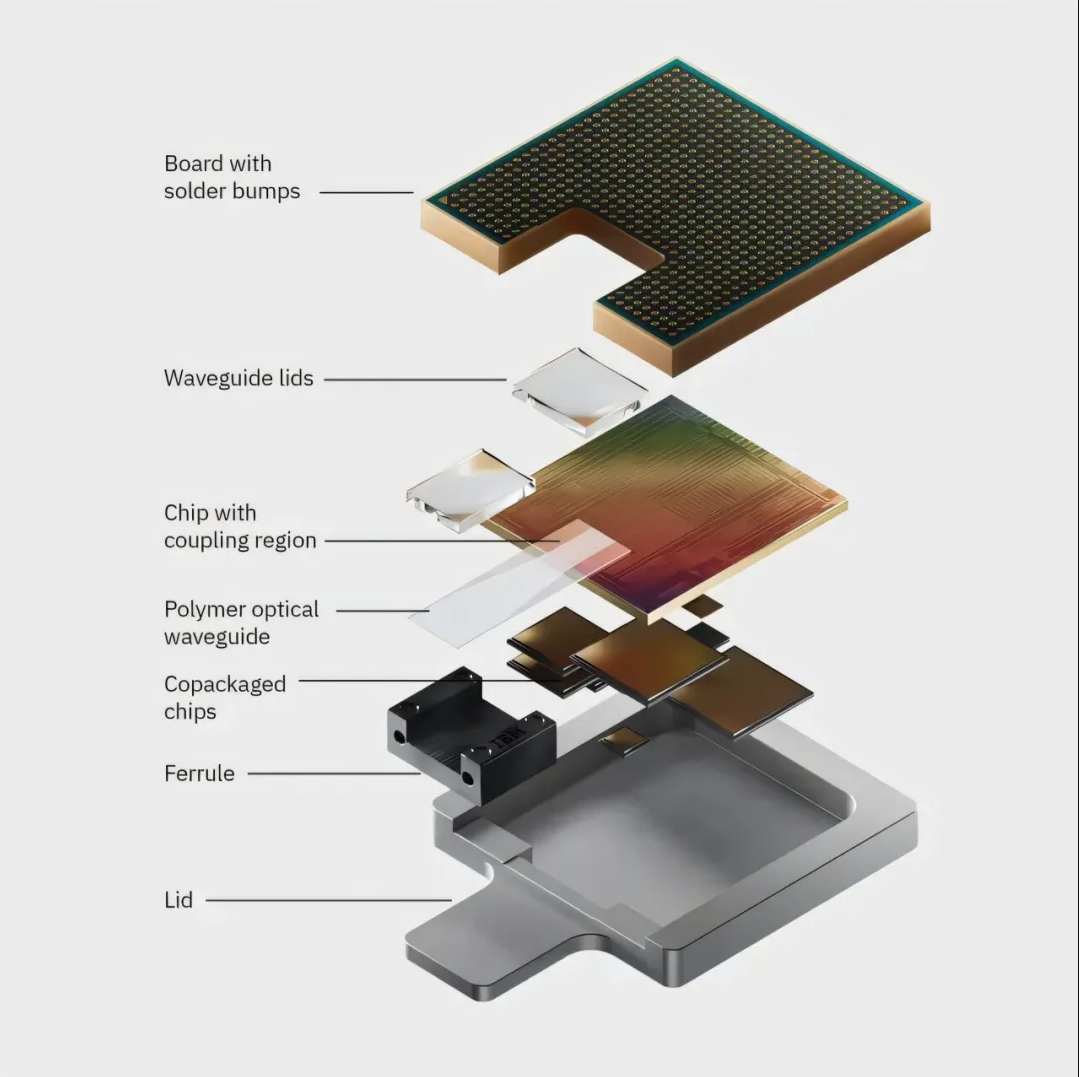

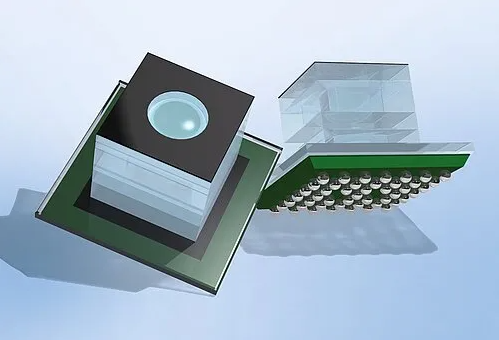

CPO(Co-Packaged Optics)is essentially an integrated solution that combines optical modules for signal transmission with data processing chips, forming a unified system. This approach works like having both a "delivery hub" and a "processing center" in the same location – eliminating intermediate steps in logistics while dramatically boosting data transfer speed & efficiency.

In scale-out network architectures, CPO enables high-bandwidth connections between racks with equal length, delivering lower latency and reduced power consumption. This technology seamlessly integrates with AI-powered cloud networks and Ethernet/InfiniBand systems. While computing nodes currently rely on pluggable optical modules, the technology will gradually replace them as CPO matures.

In vertical scaling (scale-up) networks, CPO has replaced copper cables as the key solution for GPU interconnects and node-switching connections. It demonstrates superior performance in connectivity, transmission distance, and power management, making it indispensable for AI training and high-performance computing (HPC) applications. The initial deployment of CPO will prioritize scale-up networks before gradually expanding to scale-out configurations.

02.Why we need special adhesive for CPO?

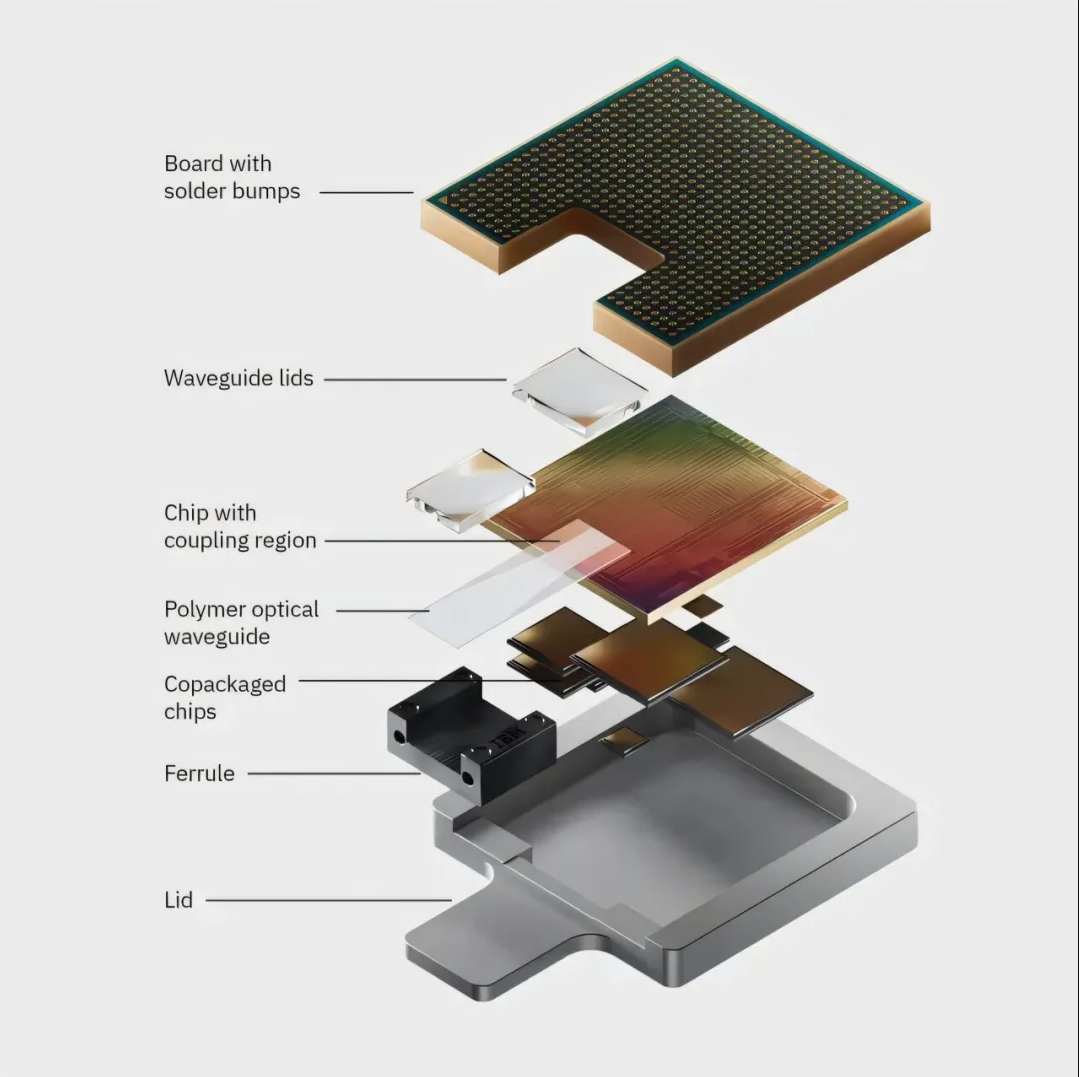

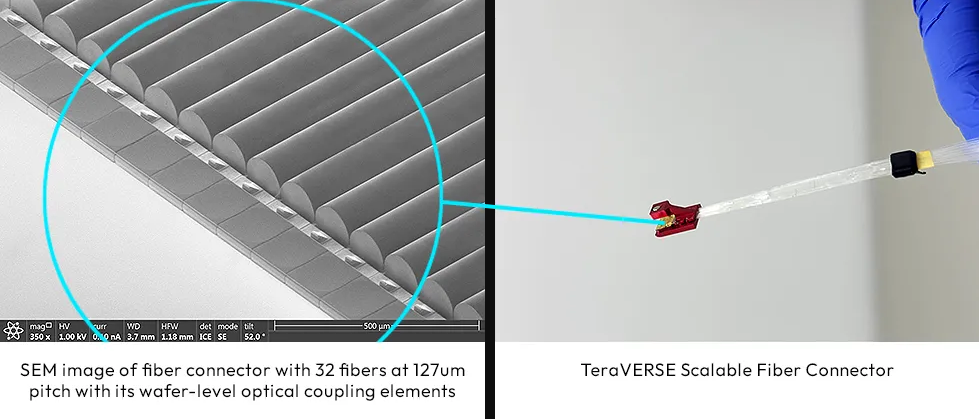

The internal structure of CPO is extremely delicate, requiring optical components to meet ultra-precision dimensional tolerances at micron or even nanometer levels. Conventional adhesives exhibit slow curing speeds and are prone to shrinkage deformation during the curing process. These defects can cause positional misalignment in optical components, compromising light signal transmission quality and potentially leading to signal interruption.

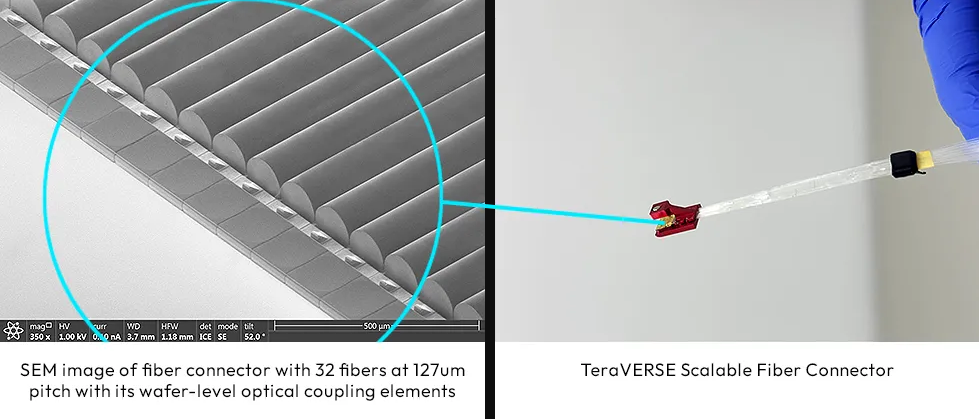

UV light curing adhesive is a special kind of adhesive, which can be cured quickly under the irradiation of ultraviolet light. It is mainly used for bonding coaxial connectors, optical fiber heads, lenses and other precision optical parts in CPO packaging, so as to fix and seal them.

Meanwhile, during high-speed operation, CPO generates substantial heat. If this heat isnt dissipated promptly, it can cause internal temperature buildup within the CPO, impairing chip and optical module performance while reducing their lifespan. Thermal management materials with excellent thermal conductivity effectively dissipate heat from heat-generating components, maintaining the CPOs optimal operating temperature.

03.How to use them in CPO?

In the CPO production process, UV-curable optical adhesives and thermal management materials work in tandem to ensure smooth manufacturing and stable operations. First, high-precision robotic arms apply UV-curable adhesive through dispensing onto the surfaces of optical components requiring bonding. Subsequently, ultraviolet irradiation triggers rapid curing within seconds, securely fastening the optical parts in place.

The thermal management material is then installed in the heat-generating areas of the CPO, tightly adhering to components like chips and optical modules. When the CPO operates, the generated heat is rapidly conducted through this material to external cooling devices such as heat sinks or fans, ensuring effective heat dissipation. These two elements act like "precision engineers" and "cooling specialists," working together to guarantee the CPO operates efficiently and stably.

04.AlphaPro® can offer what?

Globally, NVIDIA, a leading enterprise in the AI field, has extensively applied CPO technology. Its DGX system utilizes CPO technology to meet the ultra-high bandwidth demands of large model training. In a recent engineers public lecture, it was mentioned that multiple interconnect materials are used in CPO packaging, and the performance of different materials directly impacts system efficiency and stability.

AlphaPro® UV-curable adhesive 7802 achieves a curing speed of up to 3 seconds, significantly boosting production efficiency compared to the industry average of 5-8 seconds. According to data from industry research firm Prismark, this efficiency improvement reduces CPO production costs by approximately 15%. Meanwhile, AlphaPro® latest UV-curable adhesive 3829 delivers bonding precision as fine as 1 micron, effectively minimizing optical signal transmission loss. According to the International Telecommunication Union (ITU), this is equivalent to an increase in the transmission distance of optical signals by more than kilometers.

On the other hand, for thermal management, AlphaPro® latest thermal gel achieves 16W/m·K, better than the industry average of 5W/m·K. According to test data from the Thermal Management Association (TIA), the higher thermal conductivity improves the heat dissipation efficiency of CPO by more than 30%, ensuring that CPO is controlled below 70℃ at full load.

In addition, both products of AlphaPro® have a wide range of temperature tolerance and can maintain stable performance in the environment of-60℃ to 1 50℃. They can adapt to the data center needs of different regions and different environments, and can provide reliable guarantee for the stable operation of CPO products.

05.About the Future

By integrating optical modules with switch ASICs or processors, CPO enables long-distance, high-bandwidth connectivity, making it ideal for AI training and high-performance computing (HPC) applications. According to Yole Intelligence forecasts, the CPO market is projected to reach $46 million in 2024, with an expected growth to $8.1 billion by 2030, achieving a compound annual growth rate (CAGR) of 137%.

In such a market context, Elfa New Material will keep up with the international cutting-edge technology hotspots, continue to invest in research and development, constantly improve product performance, and provide customers with high-performance and high-reliability material solutions.

What else from CPO industry leaders you'd like to know? Any questions about the performance of our companys optical communication UV-curing adhesives and thermal management materials in CPO applications? Feel free to share your thoughts in the comments section.