Hotline:400-668-5636

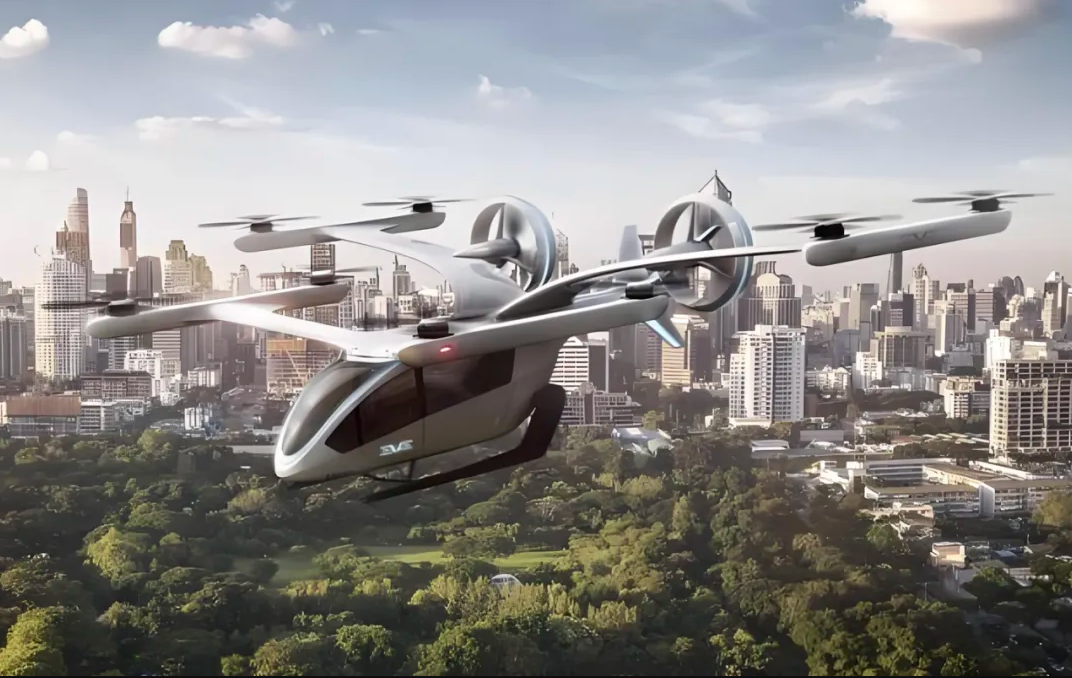

With the acceleration of urbanization, traffic congestion has become a common problem in cities around the world. eVTOL (electric vertical take-off and landing aircraft) has become the core carrier of urban air traffic (UAM) in the future due to its characteristics such as electrification, low noise and vertical take-off and landing.

As an innovative product integrating aerospace and new energy technologies, eVTOL not only boasts the environmental advantage of zero emissions but also efficiently utilizes three-dimensional space, reshaping the mobility landscape. The market is eagerly anticipating the prospects of eVTOL. According to Morgan Stanleys forecast, the global eVTOL market size will reach $1.5 trillion by 2040. Numerous aviation giants and tech companies are actively laying out their strategies, from research and testing to commercial operations, making eVTOL move from concept to reality.

However, the road to mass production is not smooth. The reliability, lightweight and high performance of materials for aircraft have become the key challenges facing the industry.

💬 Structural Connection Reliability

During eVTOL flight, the battery, propulsion system, fuselage and other components need to withstand multiple stresses such as vibration and temperature change. The traditional connection mode is difficult to meet the stability requirements under high-frequency vibration, and the failure of component connection will directly threaten flight safety.

💬 Thermal management system

The operation of the battery and power system relies on accurate thermal management. If heat cannot be dissipated, performance will decline. The thermal material needs to balance between efficient heat conduction and structural adaptation, which is difficult for traditional cooling solutions to meet the compact space requirements of eVTOL.

💬 Sealing protection

The external environment of the aircraft is exposed to wind, rain and ultraviolet light, while the internal environment needs to ensure system stability. If the weather resistance of the sealing material is insufficient, it is easy to have water leakage and dust entry problems, which will affect the accuracy of flight control and the riding experience.

💬 Lightweight and high strength

In order to improve the endurance, eVTOL needs to ensure the structural strength on the basis of lightweight. If the weight of the material exceeds the standard or the strength is insufficient, it cannot meet the flight requirements. Balancing the two becomes the key to mass production.

Battery system

■ Battery box and bracket fixing

AlphaPro High strength structural adhesive, tensile shear strength>15MPa, -40℃~120℃ stable, excellent weather resistance. No matter extreme temperature or vibration impact, it can ensure the battery box and bracket are firmly connected, protecting the safety of the battery.

■Battery module thermal conductivity

The high thermal conductivity gel has a thermal conductivity of 12.0W/ (m·K) to conduct heat quickly. The low thixotropic filling gap buffers the vibration displacement, avoids the performance attenuation caused by heat accumulation, and improves the reliability of the battery.

■Blade bonding

The tensile and shear strength of epoxy structural adhesive is>12MPa, and the fatigue resistance is outstanding, which can deal with high-frequency vibration. The thermal conductivity of 0.8W/ (m·K) is used to assist heat dissipation, so as to prevent the components from being damaged due to heat and ensure the stability of power transmission.

Machine structure

■Internal beam & seat reinforcement

StroBond's Resilient polyurethane structural adhesive has a fracture elongation of more than 200%, absorbs impact energy, and is excellent in oil resistance. It ensures that the internal components are firmly connected regardless of bumps or acceleration, improving safety and comfort.

■ External surface sealing

Silicone rubber sealing has a weather resistance of more than 20 years, maintaining elasticity from-60℃ to 200℃, and adhering to the curved structure. Waterproof and dustproof, it prevents ultraviolet erosion and protects the body and flight control system.

Detailed protection

■ External seam sealing

Polyurethane sealant has excellent water resistance, rapid curing, strong adhesion to a variety of materials. It forms a sealing barrier to prevent external damage and prolong the life of aircraft.

■ Rapid assembly of components

The initial curing of rapid curing epoxy glue is 10 minutes, and the shear strength is>8MPa, which meets the requirements of lightweight. It improves assembly efficiency and helps eVTOL to accelerate mass production.

Summary

In the wave of the trillion-dollar eVTOL market, AlphaPro is willing to use technology as its wings, working together with the industry to overcome challenges, injecting power into future air mobility with professional solutions, and ushering in a new chapter of commercial operations!