Hotline:400-668-5636

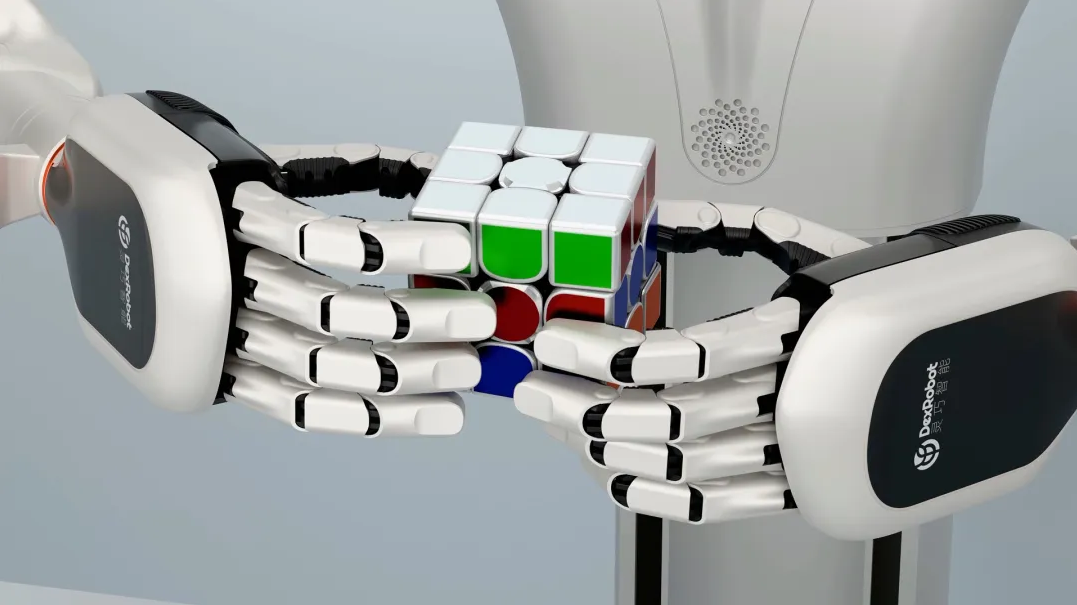

In todays era of deep integration between artificial intelligence and robotics, embodied intelligence (Embodied AI) is becoming a cutting-edge direction in the field of smart manufacturing. These robots simulate human perception and motor systems, possessing capabilities for environmental interaction, autonomous decision-making, and physical manipulation. The core lies in achieving a closed-loop system of "perception-decision-execution." According to McKinsey, the global embodied intelligence market will exceed $450 billion by 2030, with widespread applications in industrial manufacturing, medical rehabilitation, and service robots. Star products like Boston Dynamics Spot, CloudMinds Cloud Pepper, and Teslas Optimus are all pushing the boundaries of the industry.

However, in the development of embodied intelligent robots, there are three core technical challenges:

1. Flexible drive system: it needs to simulate the dynamic response of human muscles

2. Precision sensing system: environmental perception with millimeter level accuracy

3. Human-computer interface: a safe and reliable biocompatible connection is required

AlphaPro as a pioneer in the field of material innovation, we have developed four adhesive solutions to address these three challenges and help break through key technical bottlenecks.

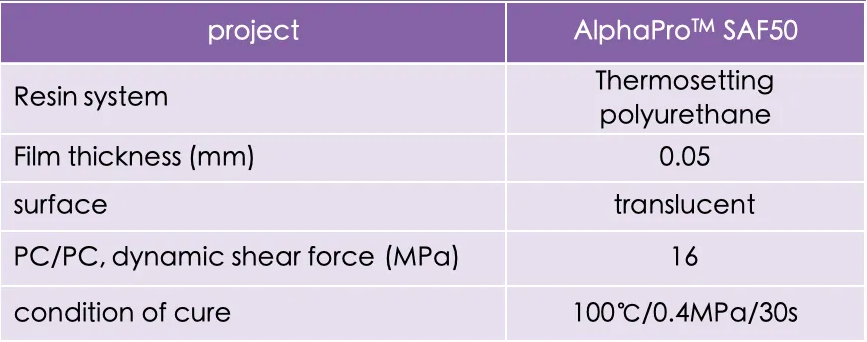

Thermosetting Film SAF50

In joint structures that require high reliability connections, AlphaPro's classic SAF50 low temperature thermosetting film has shown unique advantages:

■100℃/30 seconds rapid curing, adapted to the production line beat of automation

■ 18N/cm peel strength and 16MPa shear strength to ensure structural stability under dynamic stress

■Built-in release paper design, support complex curved die cutting processing

■Polyurethane crosslinking system achieves 100% solvent free volatilization and maintains stable elastic modulus in the wide temperature range of-40℃ to 120℃

Typical applications

■Multimaterial composite connections of bionic finger joints (such as Boston Dynamics multi-finger dexterous hand)

■Integrated packaging of flexible sensor arrays and driver elements (for use in DART Technologys service robots)

■Stress buffering of the tendon-skeleton interface in humanoid robots (such as the lower limb drive system in Honda ASIMO)

"Visual Nerve" of the Precision Optical System

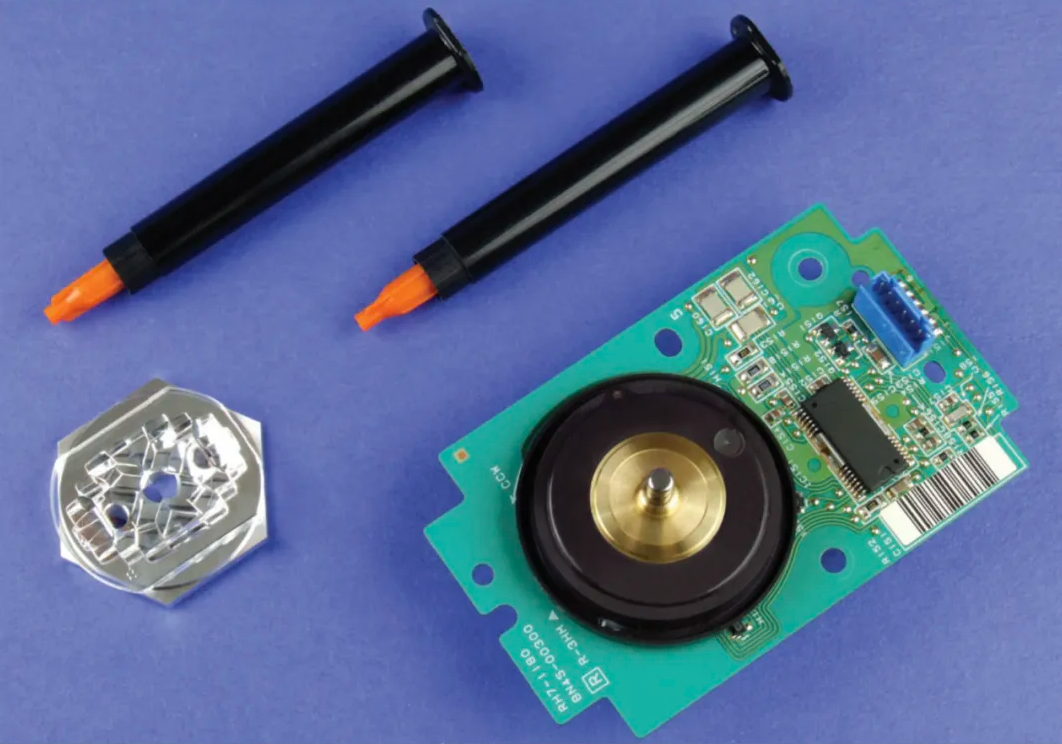

Prism CMOS Epoxy Encapsulant

6501

For the miniaturization packaging requirements of camera modules, AlphaPro New Materials newly developed one-component epoxy resin 6501 can meet the following requirements:

■ 65℃ Low temperature curing for 35 minutes to protect sensitive optical components

■The elastic modulus of 1.75GPa matches the thermal expansion coefficient of glass and metal

■ 16.5MPa shear strength ensures optical alignment in a vibrating environment

■Nanoscale filler dispersion technology to achieve precision coating with <5μm line width

Technical Breakthrough

■The curing shrinkage rate is reduced to less than 1% by optimizing the curing kinetic model

■Vacuum degassing process is adopted to eliminate bubbles at the interface of optical components

■The humid heat aging test shows that the 500-hour yellowing index ΔE is less than 1.5 in the double 85 environment

Typical Applications

■Multi-camera module packaging (for SONY IMX series image sensors)

■TOF sensor protection (such as Apple Face IDs 3D structured light module)

■Industrial camera seismic fixation (such as Cognex Vision System)

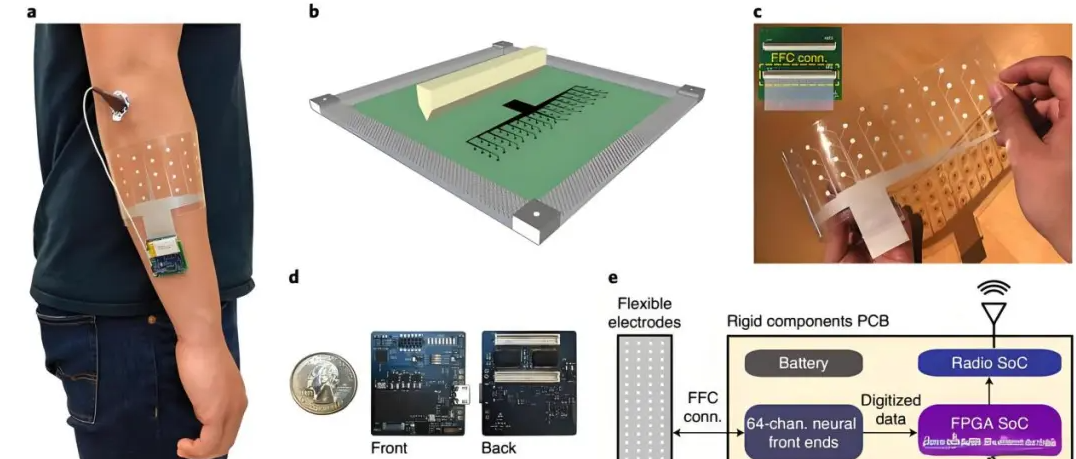

"Skin Touch" of the Human-Computer Interface

Low VOC Transfer Film 4670

In the need for environmentally safe wearable devices, AlphaPro 4670 adhesive film can realize:

■Total VOC <10ppm, in line with medical grade contact standards

■ 16N/25mm steel plate peeling force, suitable for TPU/PET and other elastic substrates

■50-60℃ heating and pressing process, supporting curved screen bonding

■The asymmetric release force structure can achieve the precise transfer of 0.07mm ultra-thin adhesive layer

Innovative applications:

■ Integration of flexible display and haptic feedback modules (such as Huawei Mate X series foldable screens)

■Non-invasive skin patches for wearable sensor arrays (biological sensors suitable for Xiaomi Band)

■Shock-resistant fixation of eye-tracking cameras in VR headsets (such as Meta Quest 3s eye-tracking system)

"Transparent Bridge" of Optical Sensing Syste

ultra-high transmittance UV 9701

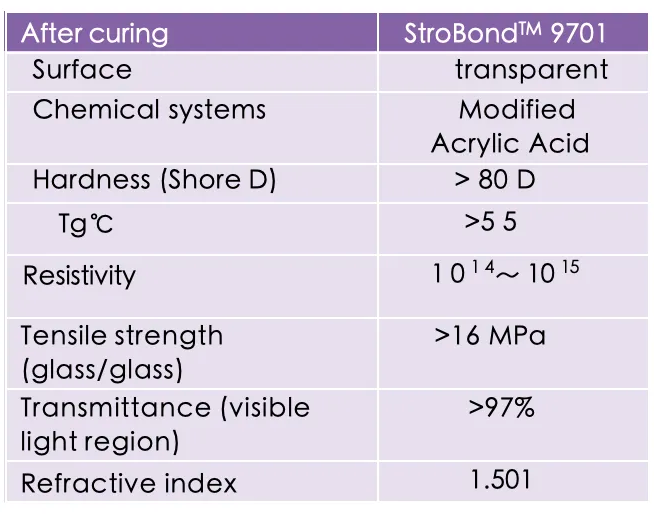

In optical systems such as AR glasses, StroBond's single-component UV curing adhesive 9701 can achieve the most demanding requirements in optical device bonding applications:

■ Light transmittance is>97% with a thickness of 25μm and the dispersion coefficient is <0.002

■1.501 refractive index matching optical glass to eliminate interface reflection

■Water absorption rate of 1.2% ensures the optical stability in wet and hot environment

■Passed the 2000-hour QUV accelerated aging test with ΔE<1 yellowing index

Technologica Superiority

■Double curing system design (UV + moisture) to achieve deep curing

■Surface tension optimization technology to ensure self-assembly of micro-lens arrays

■The edge precision of laser cutting reaches ±10μm, which meets the requirements of precision optics

Typical applications

■Optical waveguide lens bonding (such as Microsoft HoloLens 2 optical solution)

■Micro-lens array packaging (for Magic Leap light field technology)

■ Fixing of optical elements in the HUD (such as the augmented reality projection system of BMW iX)

From mm-scale microelectromechanical systems to nanoscale bionic structures, AlphaPro Adhesive solutions are reshaping the manufacturing paradigm of embodied intelligent robots. We provide full process technical support from material selection to process optimization, helping customers achieve seamless connection from prototype development to mass production delivery.