Hotline:400-668-5636

Optical communication components are like the "building blocks" of optical communication systems and networks; they are the most fundamental parts. Various types of optical components are not only indispensable "parts" in optical communication systems but also their performance and quality can significantly impact how smoothly and reliably the entire system operates. Additionally, the adhesives used to bond these optical communication components together are also crucial for maintaining the quality of the components.

Let’s talk about the optoelectronics industry, where products come in a wide variety of forms. There are light-emitting diodes and laser diodes, optical components like lenses and prisms, optical communication products such as optical fibers and cables, display devices including liquid crystal displays and organic light-emitting diodes, optical instruments like microscopes and telescopes, laser equipment such as laser marking machines and laser cutting machines, photoelectric sensors like photoelectric encoders and photoelectric proximity switches, photovoltaic products like solar panels and solar street lights, and lighting products like LED lamps and energy-saving lamps. These are all common products in the optoelectronics industry.

These products have been widely used in many fields such as communication, medical care, industry, scientific research and military, which has brought countless convenience and progress to our life and social development!

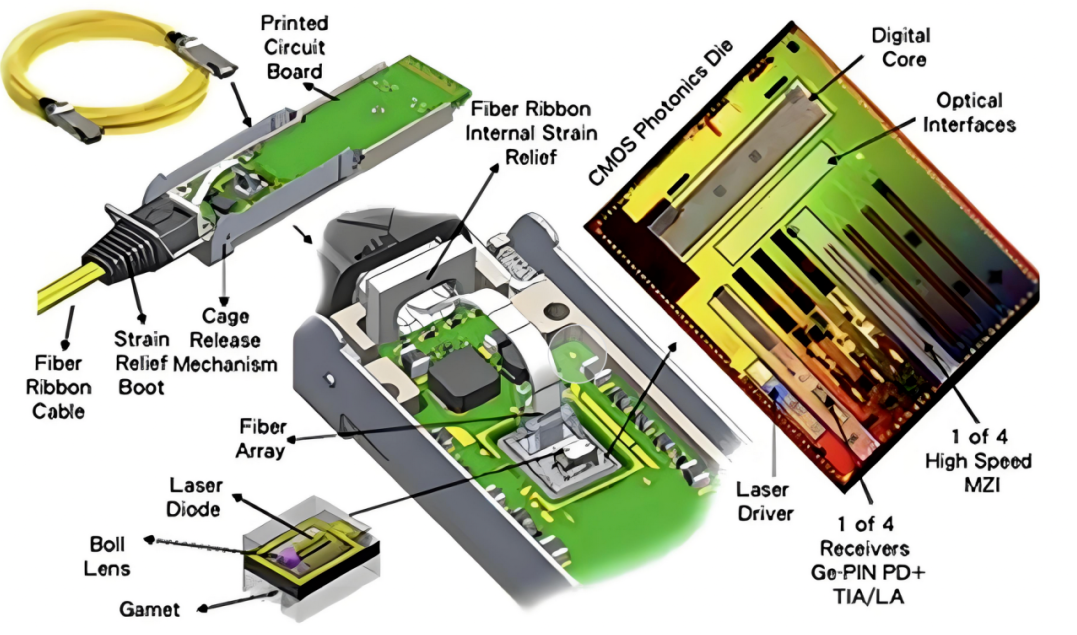

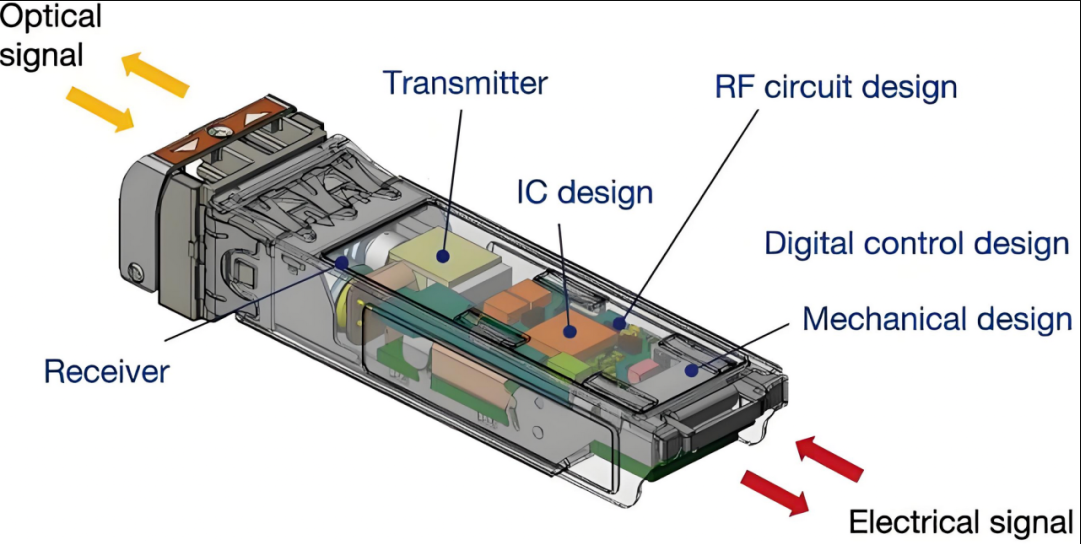

Let’s talk about the changes in optical modules, which require higher and higher performance requirements for adhesives.

The challenge of moving from a 4*25G laser to an 8*50G or 4*100G laser:

• Higher broadband

• The power of optical modules increases from 3~5 to 12~20W

The transition from QSFP28 packaging to QSFP DD/silicon optical packaging also brings higher requirements:

• The design structure is more compact

• Higher power density

• Higher integration

As a result, the performance requirements of adhesive packaging solutions used in the process have also increased:

• Low CTE and shrinkage, as well as reliable UV/UV+HEAT coupled adhesive

• Optical path adhesive with low modulus, low CTE, better resistance to yellowing and optical properties such as low/middle/high refractive index

• High thermal conductivity, low volatile solid crystal glue or thermal conductive glue

• High reliability, high stability structural fixing glue

Well, let's take a look at some of the solutions AlphaPro for the tricky optical devices:

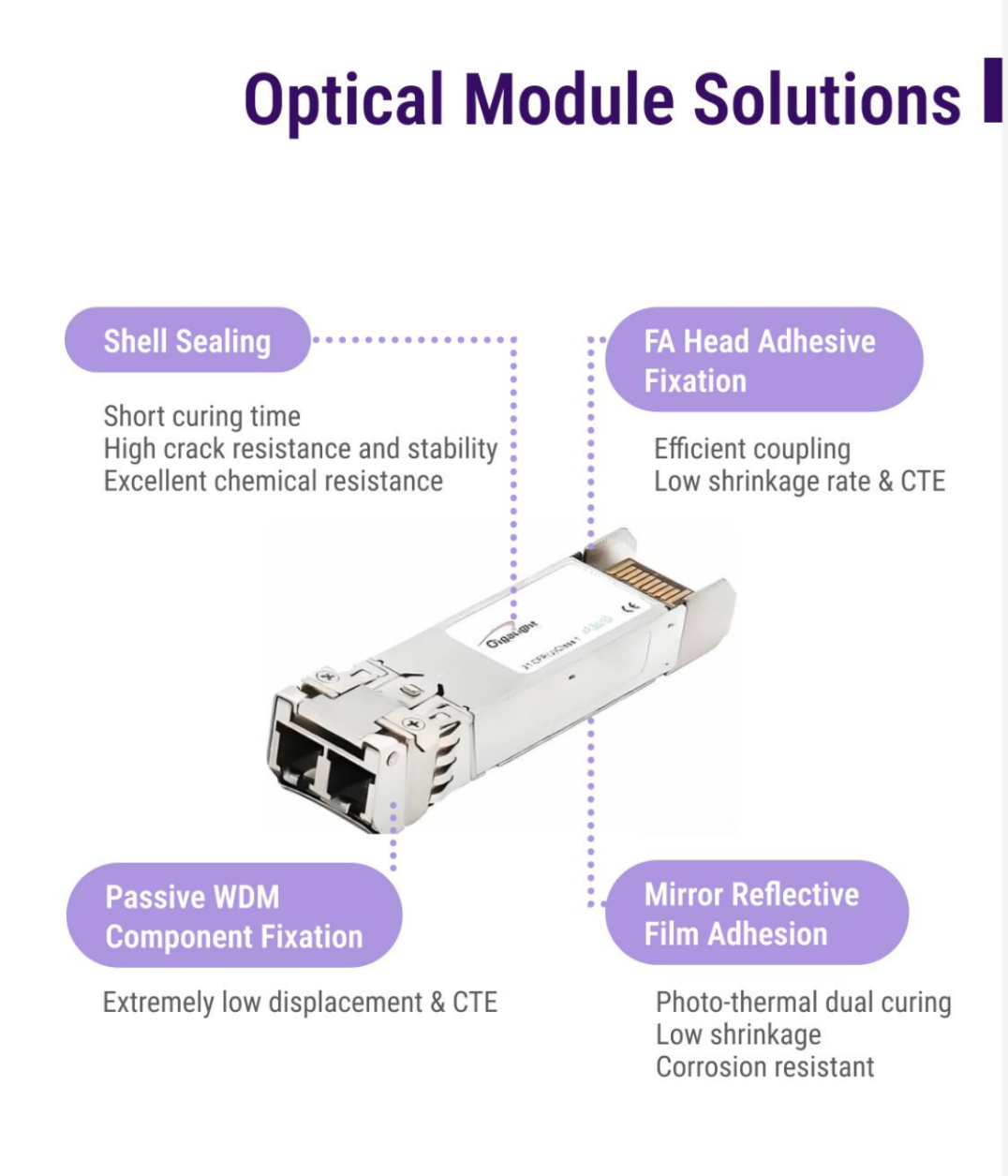

WDM device coupling

WDM is also known as wavelength division multiplexing. Essentially, it involves combining multiple light signals of different colors (or wavelengths), much like small streams of different colors, into a single "large pipe" called an combiner. These signals are then squeezed together into the same optical fiber. This method allows for the transmission of more data, increasing the capacity of the fiber while also making better use of fiber resources, making the process more efficient.

There are two main types of products that use WDM technology, one is CWDM, which is coarse wavelength division multiplexing, and the other is DWDM, which is dense wavelength division multiplexing. Now you know a little bit about WDM.

AlphaPro successfully developed a high-standard photothermal dual-curing adhesive, —— A lphaOCX12, utilizing mature foreign technology. It not only meets the market demand for high-performance encapsulation adhesives but has also been widely applied in many well-known domestic companies for the fixation and packaging of passive wavelength division multiplexing (WDM) devices, including coarse wavelength division multiplexing (CWDM) and dense wavelength division multiplexing (DWDM). A lpha OCX1, with its extremely low displacement and extremely low thermal expansion coefficient, has broken the long-standing dominance of international markets in this field, offering customers shorter lead times and better storage stability.

OCX12 features an extremely low coefficient of thermal expansion. In optical module packaging (such as 400G high-speed modules), it can support optical coupling precision within 3 microns, reducing optical signal loss. With an extremely low shrinkage rate of 1%, it far outperforms the common 3-5% in the industry, further minimizing optical component displacement caused by shrinkage or expansion. Additionally, its high light transmittance of 97% fully meets the requirements for optical signal transmission. It is suitable for lens bonding and fiber array packaging in optical modules, including the fixation of filters and isolators in DWDM devices. Notably, our application scenarios also cover AA focusing in lidar modules and automotive camera modules.

Turning Mirror

Rotating mirror, also known as a polygonal scanning mirror. The rotating mirror is essentially a hollow cylinder with multiple sides, each side coated with a reflective sheet. Its primary function is to reflect the laser beam, enabling it to scan rapidly and accurately. This small component is highly utilized in LiDAR systems! To enhance the strength and stability of the reflective sheet, we typically add an additional layer of reflective film on its outer surface. To ensure that the reflective sheet remains lightweight yet maintains a uniform mirror surface, we usually use an adhesive method to attach the reflective film.

At this time, the glue used is very critical. Because this part is special, so the requirements for glue are very high, must keep low stress, so as not to have a bad impact on the lens, and at the same time, the strength is high, so that the reflective film is firmly glued.

AlphaPro's OCX24, a glue specifically designed for the photothermal dual-curing process. It demonstrates excellent adhesion on the surface of anodized materials. This glue is particularly suitable for tightly bonding reflective film sheets with mirrors, ensuring stability and durability in various applications while offering low shrinkage, superior bonding strength, and corrosion resistance.

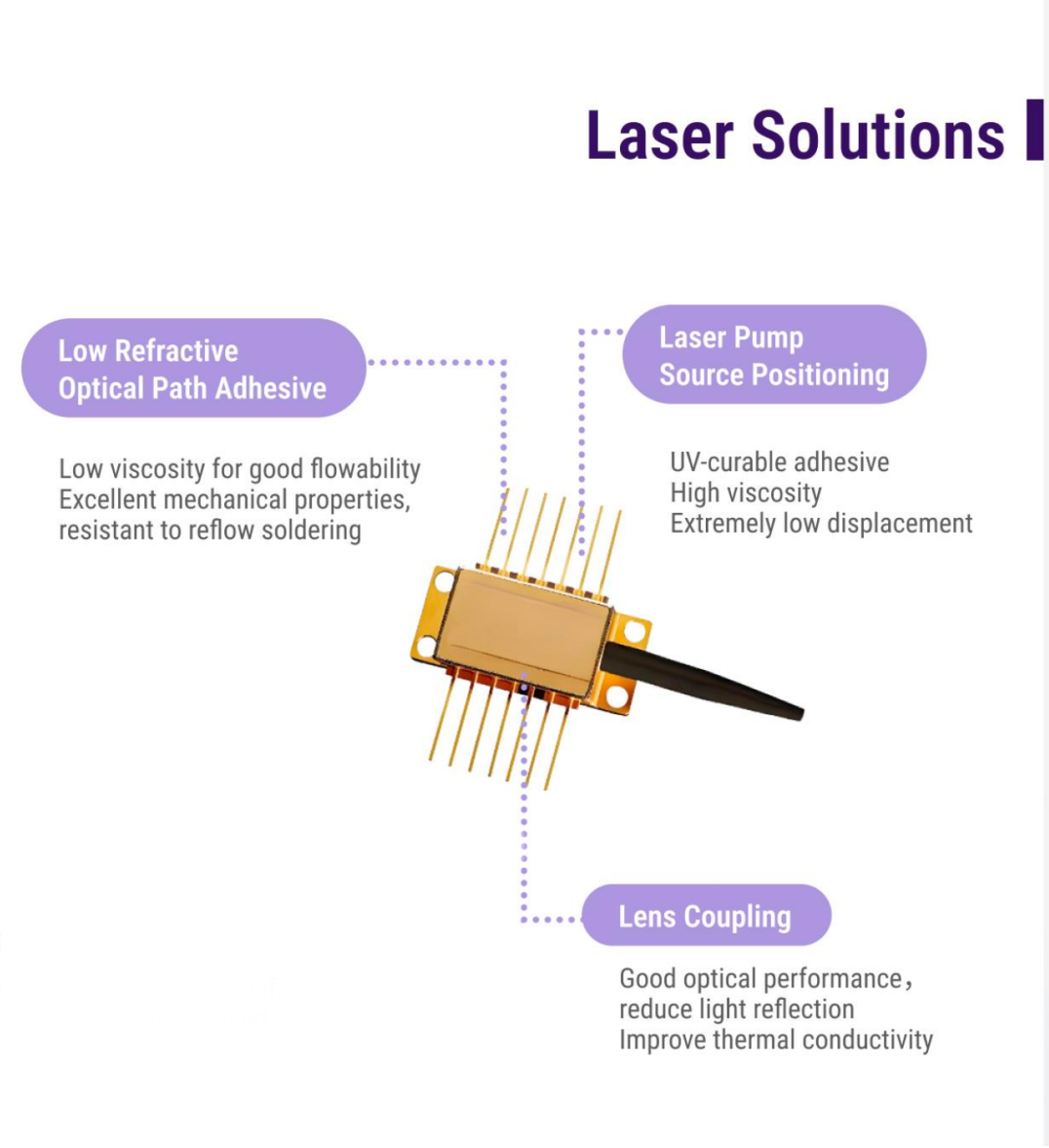

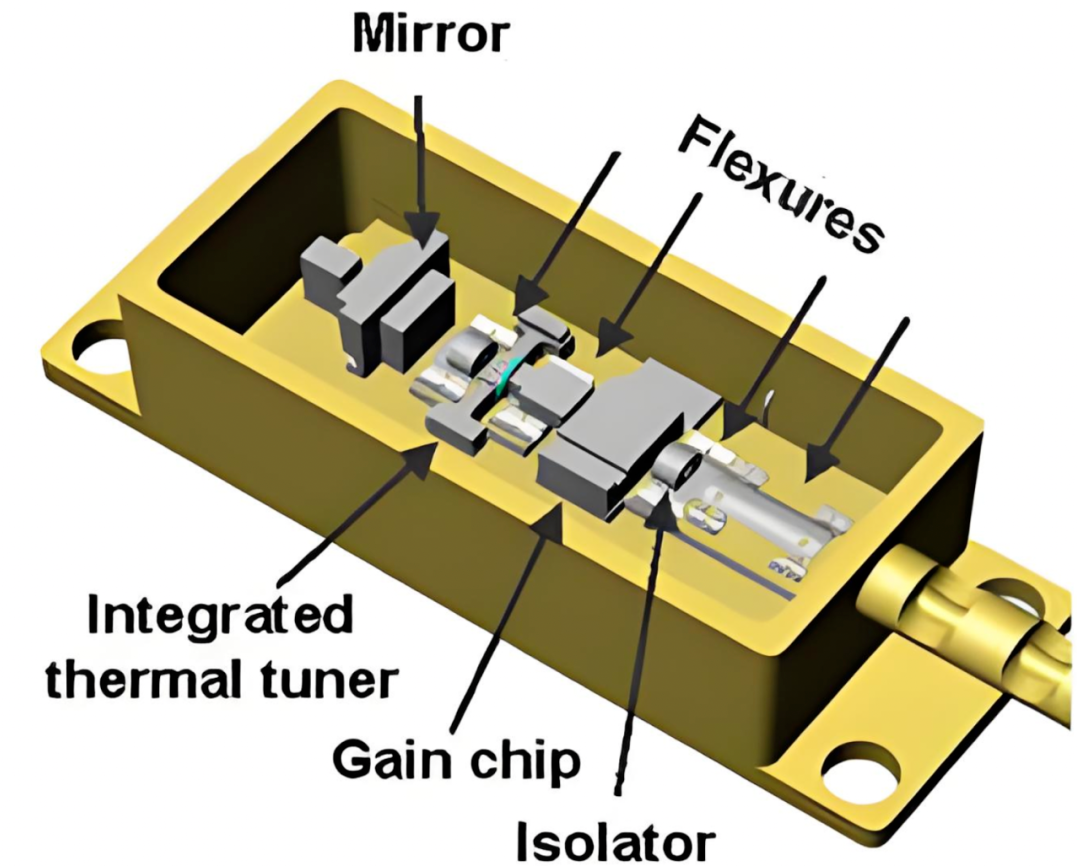

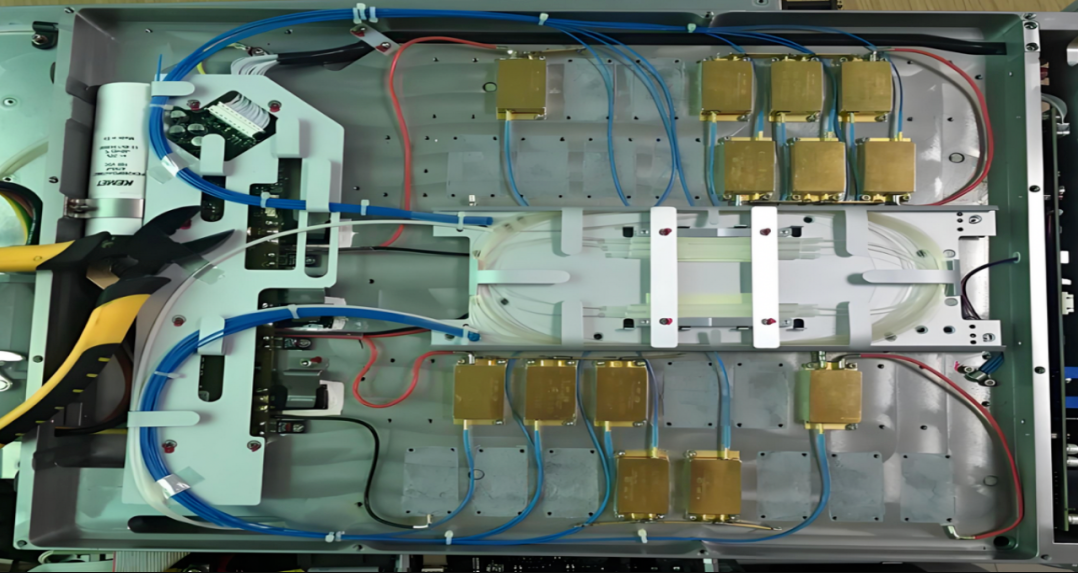

Pump Source

The pump source contains several chips that, when the semiconductor laser is generated, are collimated by an optical system and then "fed" into a multimode fiber to produce high-intensity lasers.

。

The laser beam emitted by the semiconductor laser chip is typically elliptical. It has a larger divergence angle in the vertical direction, but the beam quality in this direction is excellent, which is referred to as the "fast axis." In contrast, the divergence angle in the horizontal direction is smaller, and the beam quality is not as good, hence it is called the "slow axis."

In order to get better coupling of the laser, just as in order to get better "teaming" of the laser into the fiber, we need to collimate the beams in these two directions separately. The components used for this work are called fast axis collimation (FAC) and slow axis collimation (SAC).

Among them, the coupling positioning of the FAC fast-axis collimating lens is crucial for laser intensity. Therefore, there are specific requirements for the UV glue used here. AlphaPro's OCX37 UV-curable adhesive, with its high viscosity, precise fixation, heat resistance, rapid positioning, and minimal displacement, is widely applied in the positioning of laser-pumped sources such as FAC and SAC.

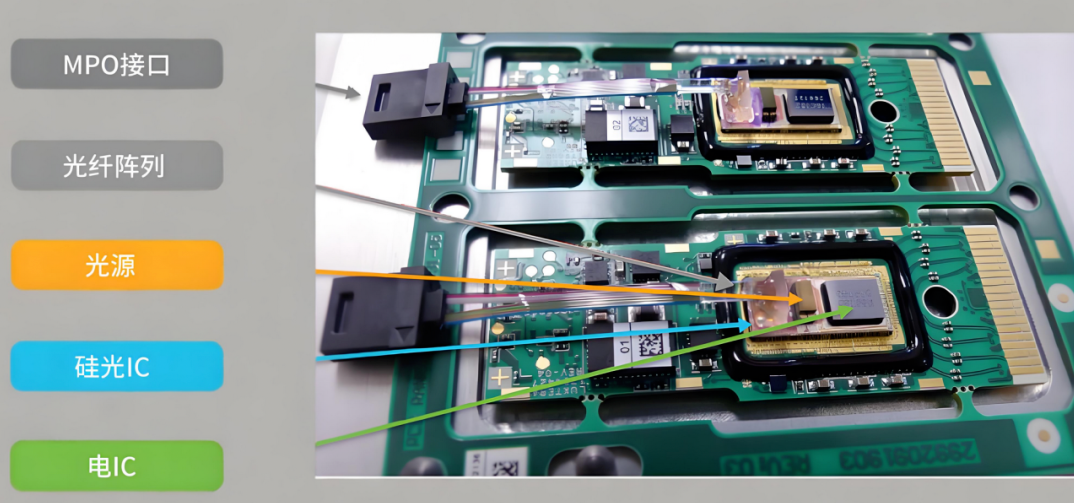

Fiber array

By bundling multiple optical fibers together, it can be imagined as many straws placed in a small box—this is an optical fiber array. This optical fiber array creates a highly efficient and stable channel for light signal transmission, much like building a super highway. It also makes optical communication systems more flexible, allowing them to be combined and expanded like building blocks.

This fiber array is the absolute MVP in optical communication systems. The key material used is called FA head glue, specifically designed for FA (Fiber Array). To keep up with industry advancements, AlphPro's OCX42, is specifically designed for passive splitters FA positioning. Its features include high-temperature resistance, high humidity tolerance, and strong fluidity, effectively ensuring the stability of the fiber array and achieving efficient optical coupling. In the design and manufacturing of optical communication systems, selecting appropriate FA head glue and strictly controlling quality is crucial.

The following are specific application scenarios of StroBond in optical communication products. If you are interested in any of the products or applications, please feel free to click on the original text to contact us.