Hotline:400-668-5636

In todays digital wave, TV plays a key role in many industries.

System integration relies on TV screen to realize visual interaction of intelligent devices and help efficient operation;

Entertainment uses special effects on TV to create a stunning performance;

Advertising media promote brands through the powerful communication power of TV;

The engineering design uses TV to display the blueprint, which facilitates team collaboration;

The digital government uses television as a window for information disclosure;

Supermarket retail uses TV screens to attract customers and promote sales;

Security emergency uses TV to present monitoring pictures to ensure safety;

Education conferences use TV to display information and improve efficiency;

Television broadcasts of events in large venues create an atmosphere.

However, in these scenarios, we often overlook the "heroes" behind the TV: —— composite tape and adhesive

Tape inTelevision Production

1.Screen fixation and protection

In the assembly process of TV screens, tape plays an indispensable role. Alpha- Pro widely used acrylic foam double-sided tape in the screen display industry ensures a tight connection between the screen and the outer frame with its excellent cushioning properties and strong adhesive strength, guaranteeing that the screen will not shake or shift during daily use and transportation. Additionally, it has a water resistance rating of IPX8.

AlphaPro classic PET, the protective film acts like an "invisible shield" for the screen. In the production, transportation, and sales display stages of TVs, it prevents scratches, fingerprints, and dust from contaminating the screen. This protective film has high transparency, ensuring no impact on the screens performance, and can be easily removed when needed without leaving any residue. Currently, almost all 4K TVs have their screens coated with a PET protective film before leaving the factory, which helps reduce the risk of damage during transit.

2.Edge protection and stability

The aluminum foil wrapping of the TV screen is often affected by external impact, environmental temperature and humidity changes and other factors during long-term use, resulting in the lifting of the screen edge. This not only affects the beauty of the TV, but also may lead to damage of the screen edge, and even affect the stability of the internal circuit.

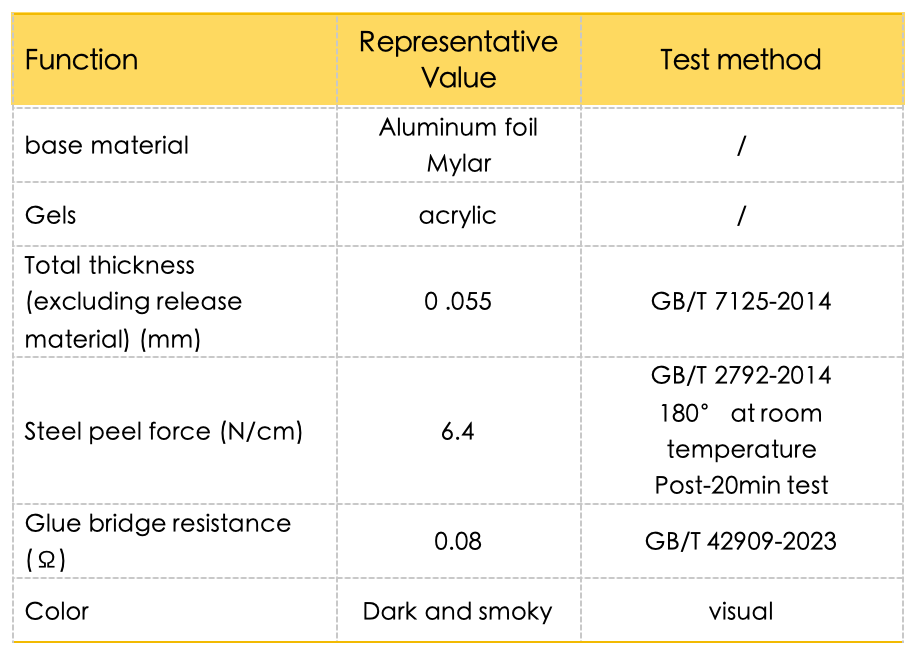

However, AlphaPro new material offers a targeted solution: —— Edge Tape for Aluminum Foil with Raised Edges 6750. This tape differs from common domestic products; AlphaPro uses imported German raw materials and a specially formulated adhesive, providing exceptional adhesion that firmly secures the aluminum foil with raised edges to the screens edge, effectively resisting various external forces that can cause the edges to lift.

At the same time, it has good flexibility and weather resistance, can maintain stable performance in different temperature and humidity environment, the internal laboratory test data shows that 1 kg weight can be maintained for 72 hours, can maintain the flatness and stability of the package for a long time, providing reliable protection for the edge of the TV screen.

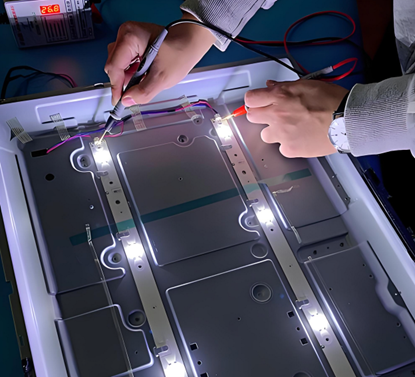

3.Part grounding and insulation

In TV motherboards and other electronic components, grounding and insulation treatments are necessary to ensure the safe operation of the equipment and stable signals. AlphaPro’s classic aluminum foil double-sided tape not only achieves screen grounding, ensuring that static electricity is promptly released, but also adheres to buffer foam for shock absorption and protection. On the other hand, AlphaPro’s innovative black PET single-sided tape is primarily used for insulating the aluminum foil edges from the frame parts, effectively preventing current leakage and enhancing the electrical safety of the TV.

Adhesives in TV Manufacturing

1.Motherboard Theraml Management

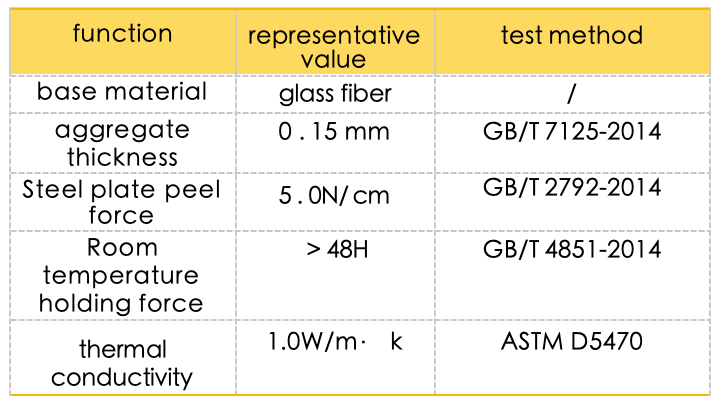

As the functions of TVs continue to strengthen, motherboard chips generate a large amount of heat during operation. If this heat is not dissipated in time, chip performance will be affected, and may even lead to equipment failure. Traditional cooling methods sometimes struggle to meet the growing demand for heat dissipation. However, AlphaPro’s latest product, the thermal double-sided tape 1507 with a thermal conductivity of up to 1W, has become a powerful solution to this problem.

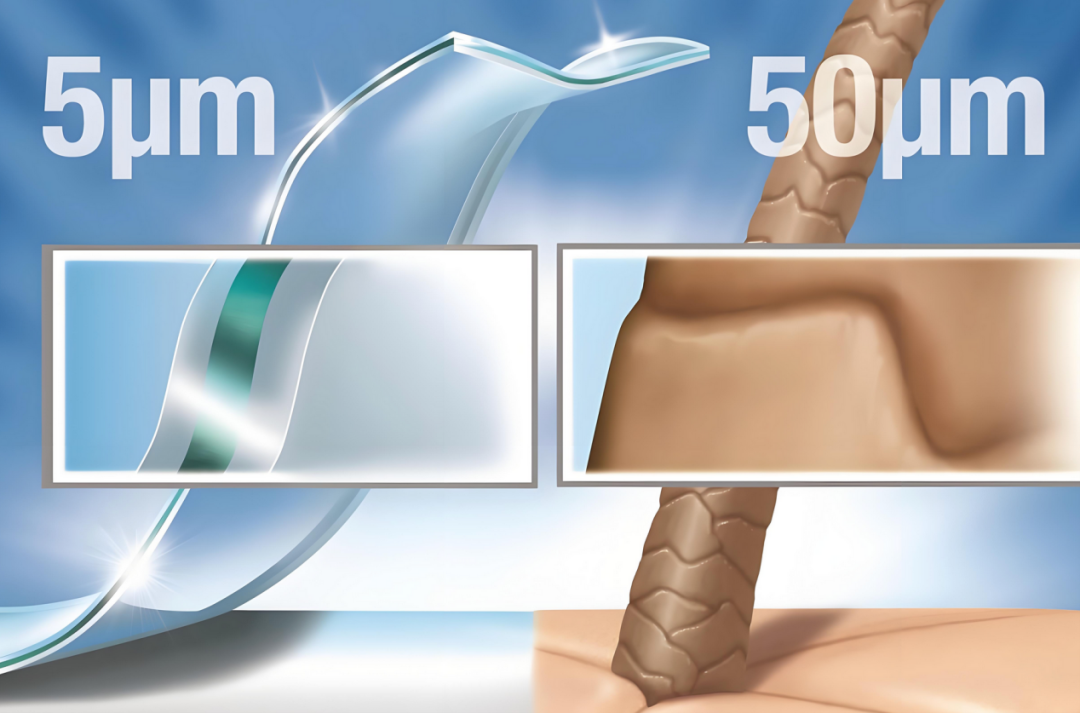

This thermal double-sided tape can efficiently transfer the heat generated by chips. Compared to ordinary adhesives, its excellent thermal conductivity significantly reduces the operating temperature of chips, ensuring stable chip operation and extending their lifespan. At the same time, while providing thermal conductivity, it also firmly adheres the chip to the heat sink, ensuring a tight fit and improving cooling efficiency, solving application issues that both thermal pads and thermal gels cannot address. Currently, AlphaPro’s advanced technology can make the thickness of the thermal tape as thin as 5 micrometers, narrower than an average human hair.

2.Component bonding

In the production process of televisions, many components need to be firmly bonded using adhesives. For example, AlphaPro’s classic UV adhesive performs excellently in bonding springs with the PC. It cures extremely fast, taking just 10 seconds under specific wavelengths of light. Moreover, it has an exceptionally high strength when bonding metals, ensuring that the spring does not fall off during long-term use, thus guaranteeing the proper operation of all related TV components.

The innovative MMA adhesive from AlphaPro is widely used for bonding various components due to its characteristics of room temperature curing, moderate viscosity, and high bonding strength. Heating can also accelerate the curing process, significantly improving production efficiency. Currently, AlphaPro has engaged in solution exchanges with multiple overseas TV assembly plants. The adhesives advantage of automatic dispensing will gradually replace traditional tapes, enhancing factory assembly efficiency.

3.Circuit protection

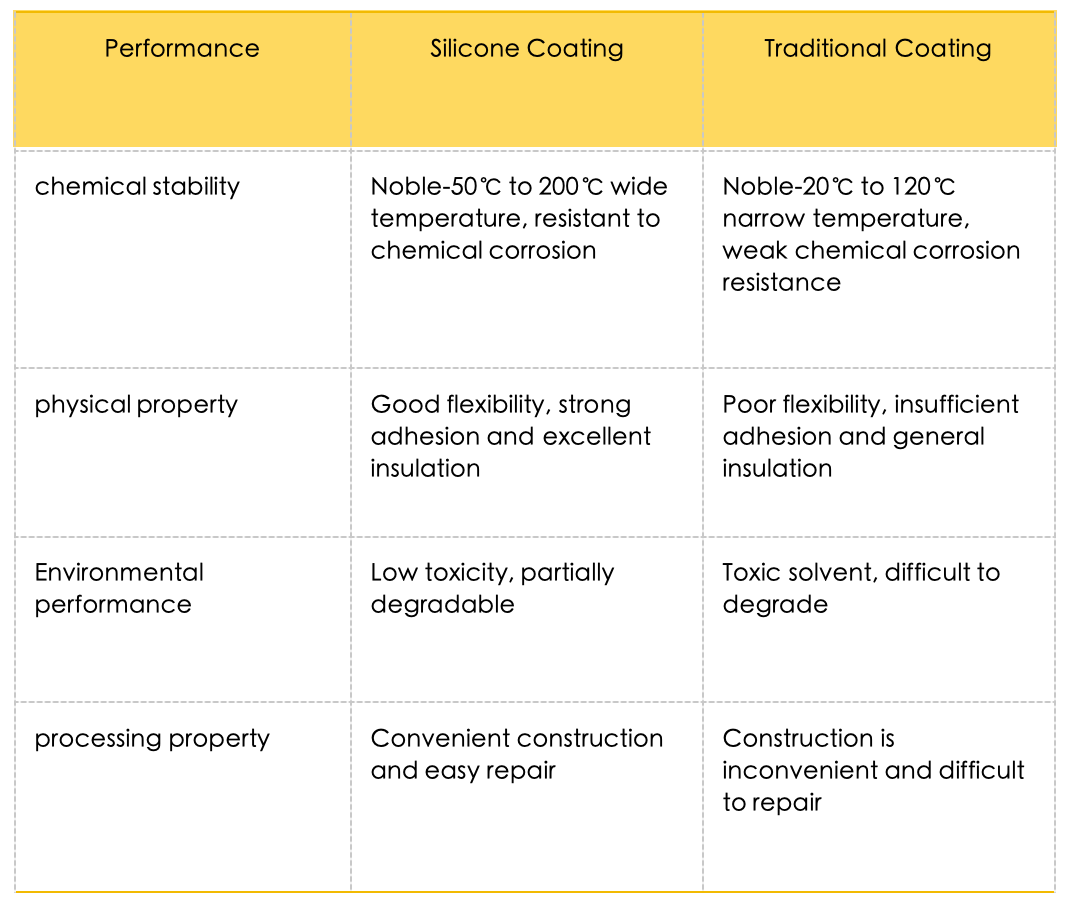

The innovative AlphaPro silicone batch coating (three-proof paint) plays a crucial role in the circuit protection of TVs. It forms a dense protective film on the surface of circuit components such as TV PCB boards. This protective film has excellent moisture-proof, dust-proof, and salt fog-resistant properties, effectively blocking external moisture, dust, and corrosive substances from eroding the circuits. It significantly reduces the likelihood of faults like short circuits and open circuits caused by environmental factors. For example, in humid coastal areas or dusty environments, the circuits of TVs treated with organic three-proof paint can maintain stable operation.