Hotline:400-668-5636

In the field of semiconductor packaging, underfill adhesive, as a key material, is used in flip-chip, stacked packaging, and 2.5D/3D integrated packaging.

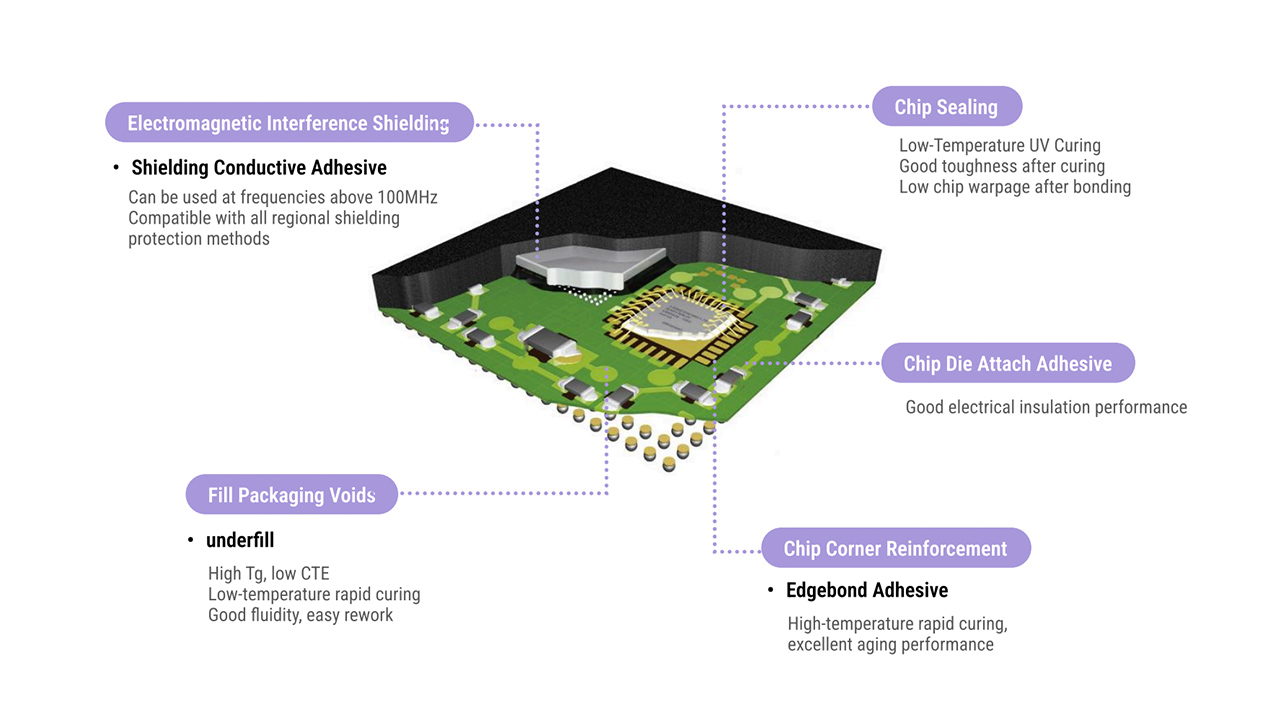

**Product application**:

- Underfill adhesive is specifically used to protect advanced semiconductor devices such as flip-chip, stacked packaging, and 2.5D/3D integrated packaging. These technologies are becoming increasingly common in modern electronic devices.

**Technical necessity**:

- Contemporary semiconductor device packaging faces challenges such as increased metal bump connection density, reduced chip thickness, increased architectural complexity, and differences in the coefficient of thermal expansion (CTE) of different materials. These factors can all affect the reliability of the device.

**Mechanical stress protection**:

- By applying semiconductor-grade underfill adhesive, mechanical stress generated during the packaging process can be effectively relieved and dispersed, thereby reducing potential damage caused by factors such as thermal cycling, mechanical vibration, or impact.

**Performance improvement**:

- The use of underfill adhesive significantly improves the overall reliability and lifespan of the package. By optimizing the mechanical stability of the packaging structure, the risk of device failure during long-term operation is reduced.

**Material characteristics**:

- This material has excellent adhesion performance, thermal conductivity, electrical insulation, and chemical stability, and can meet the operational requirements of semiconductor devices under various environmental conditions.

**Packaging process optimization**:

- The application of underfill adhesive is an important link in the packaging process. It not only improves packaging quality but also helps achieve smaller-sized and higher-performance semiconductor device designs.